which of the following is a type of machine safeguarding punching

A Servicing or maintenance is not hazardous for employees. Mechanical Engineering questions and answers.

Basics Of Machine Guarding Hazards And Solutions March

The mass of the moving parts including the flywheel is 130 kg at 750 mm radius.

. O Punching O Feeding and ejection methods O Point of operation O In-going nip points. Which of the following is a type of machine safeguarding. Machine Safeguarding 101 Rockford Systems Llc.

Typical machines used for punching operations are power presses and ironworker machines. Primary Safeguarding Methods Two primary methods are used to safeguard machines. A constant torque 3 kW motor drives a punching machine.

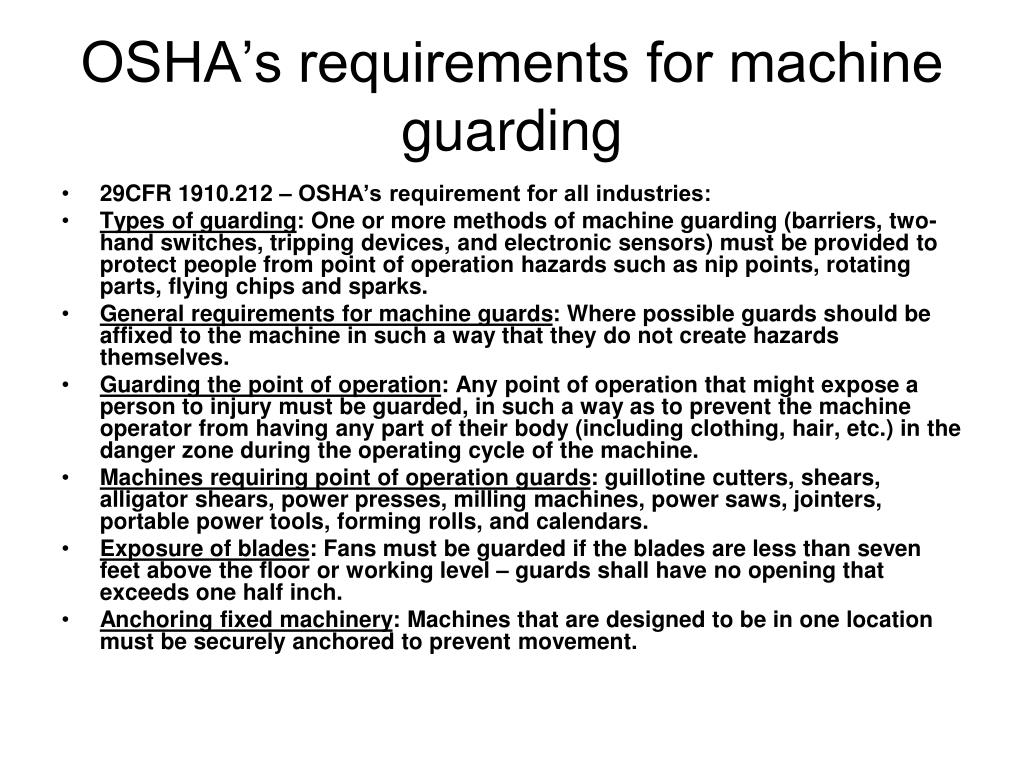

Machine guarding and related machinery violations continuously rank among the top 20 of OSHA citations issued. Which of the following is an exception to the general rule for safeguarding to prevent hazards during servicing and maintenance of machines. This problem has been solved.

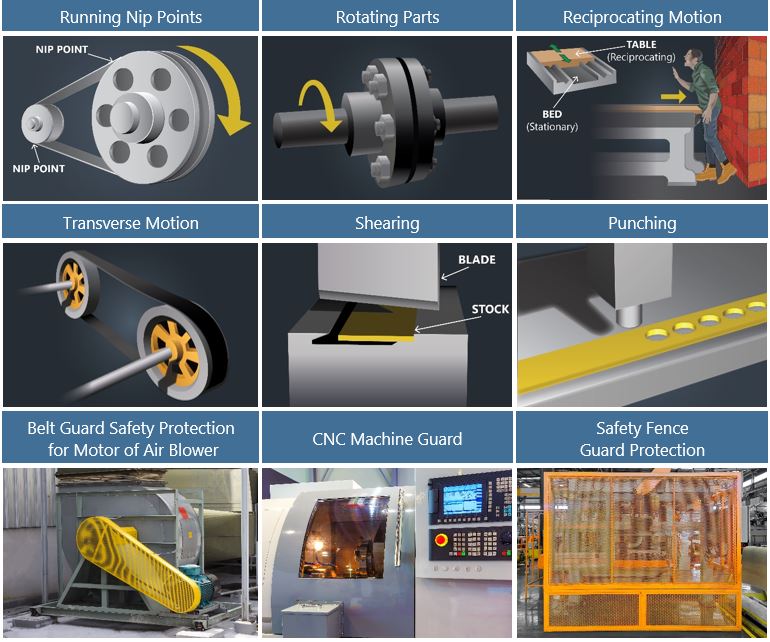

Nip guard to in-running rolls and fixed railing or fencing to engines motors planning or shaping machine are of this type. Which of the following is a type of machine safeguard. The most common types of machine guards are.

One punching operation absorbs 1 kg of energy and takes 1 s. A Punching B Feeding and Ejection methods C Poinit of operation D In-going nip points Question. Speed of the flywheel is 240 rpm before punching.

Which of the following is a type of machine safeguarding. The most common types of machine guards are. Feeding and ejection methods is a type of machine safeguarding.

Which of the following is a type of machine safeguarding. Thanks to the following individuals. Which of the following is a type of machine safeguarding punchink feeding and ejection methods point of operation in-going nip points Weegy.

Guards and some types of safeguarding devices. Also what are the 2 types of primary safeguarding methods. The danger of this type of action occurs at the point of operation where stock is inserted held and withdrawn by hand.

The type of operation size or shape of stock method of handling physical layout of the work area type of material and production requirements or limitations will help to determine the appropriate machine safeguarding method for the. A Punching B Feeding and Ejection methods C Poinit of operation D In-going nip points Question. The following are all machine safeguarding requirements except.

Which of the following is a type of machine safeguarding. Machine guards are your first line of defense against injuries. B Maintenance is minimal and.

Punching action results when power is applied to a slide ram for the purpose of blanking drawing or stamping metal or other materials.

Machine Safeguarding By Location And Distance

Ppt Chapter 14 Powerpoint Presentation Free Download Id 595562

Machinery Safety Training By Osha

Examples Of Four Primary Machine Actions

Ppt Chapter 14 Powerpoint Presentation Free Download Id 595562

Ppt Chapter 14 Powerpoint Presentation Free Download Id 595562

The Guarded Truth Answers To Machine Guarding Compliance Faqs Ensafe

Machinery Safety Training By Osha

Basics Of Machine Guarding Hazards And Solutions March

Basics Of Machine Guarding Hazards And Solutions March

System Akas Meets The Safety Requirements Of Category 4 According To En 954 And Pren 61496 And The Most Recent Require Safety Lights Light Grid Safety Devices

Basics Of Machine Guarding Hazards And Solutions March

Ppt Chapter 14 Powerpoint Presentation Free Download Id 595562

Basics Of Machine Guarding Hazards And Solutions March